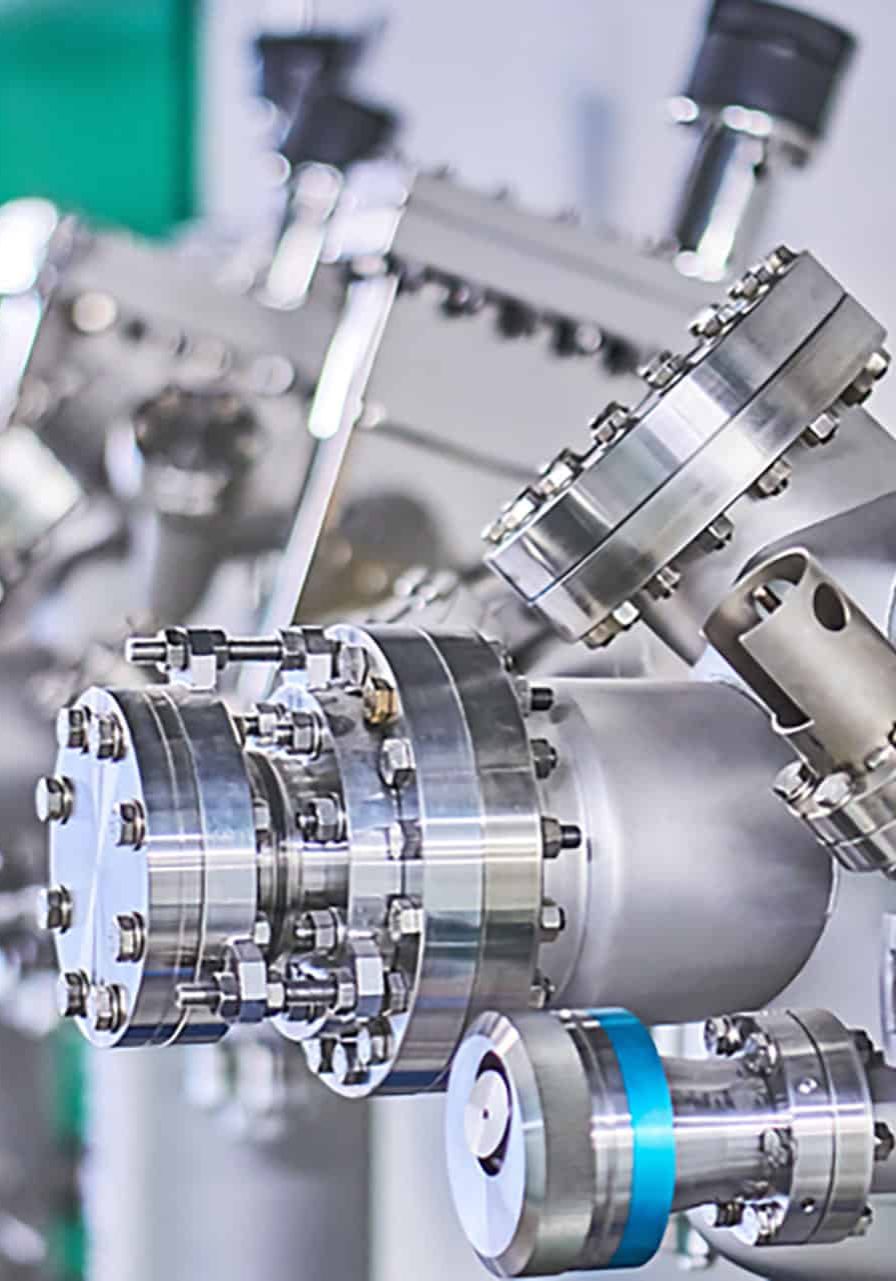

Intamet has over 25 years supplying the Vacuum market with Stainless Steel and Nickel Alloy Products. Stocking a full range of polished internally and externally stainless steel tubes ranging from 6mm OD - 609.6mm OD and the possibility of rolling and welding special dimensions.

Vacuum